Ethernet-APL is Here!

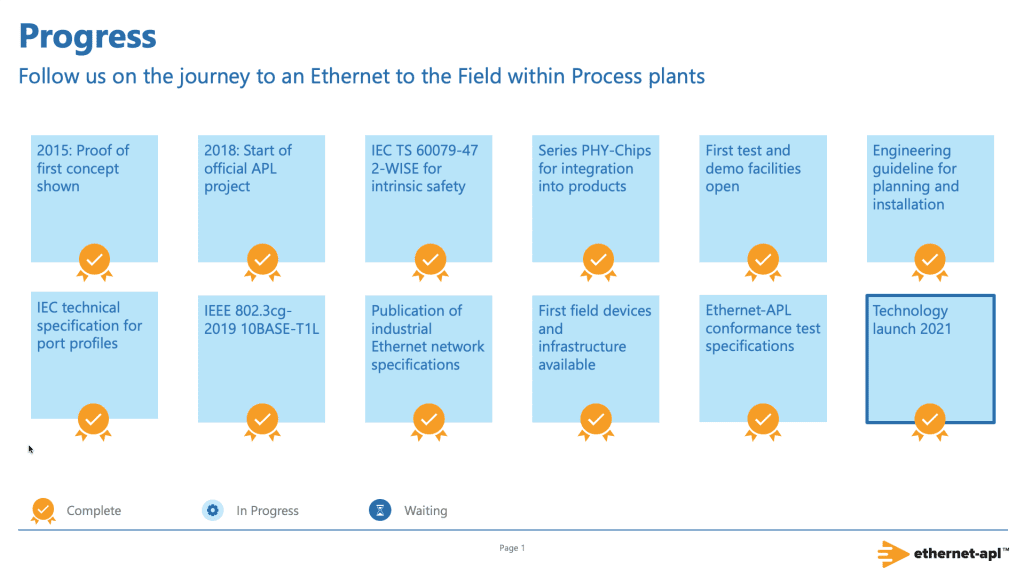

Specifications internationally standardized, conformance test plans implemented, first products released

Ethernet-APL

Modernize your plant with high speed ethernet to the field technology

Ethernet-APL Overview

Technology

A two-wire Ethernet for process automation and hazardous locations, based on IEEE and IEC standards.

Benefits

- Enhances the value generated by your process plant by bringing Ethernet technology and high-speed communication out into the field.

- Dramatically simplifies installation, configuration and maintenance of instruments and automation technology.

- Designed for a workforce trained in IP technology.

Partners

The Ethernet-APL effort is led by a collaboration of standards organizations and industry partners. Together, these companies are developing all technology, guidelines, and best practices to assure successful deployment of ethernet to the field technology.

Industry Partners

Why Ethernet-APL?

1000m Cable Length

2-Wire with Power

Designed for Intrinsic Safety

Reuse Existing Cabling

Enable Field Instruments with Ethernet

Process plants today compete to produce more product with less waste. The digital transformation motivates C-Level executives to invest in more plant data coming from process automation systems and instrumentation.

Ethernet-APL is a standardized Ethernet Advanced Physical Layer which meets all the requirements for the field of process plants.

Is Ethernet-APL for You?

End User

Ethernet-APL provides a secure, high-speed powered ethernet networking solution throughout the plant — including intrinsically safe areas.

EPC

Simplify project infrastructure planning, speed commissioning, and provide ultimate flexibility with support for all process automation communication protocols.

Supplier

Take advantage of high-speed, intrinsically safe, powered ethernet in your 21st century instrument, infrastructure, and application software designs.

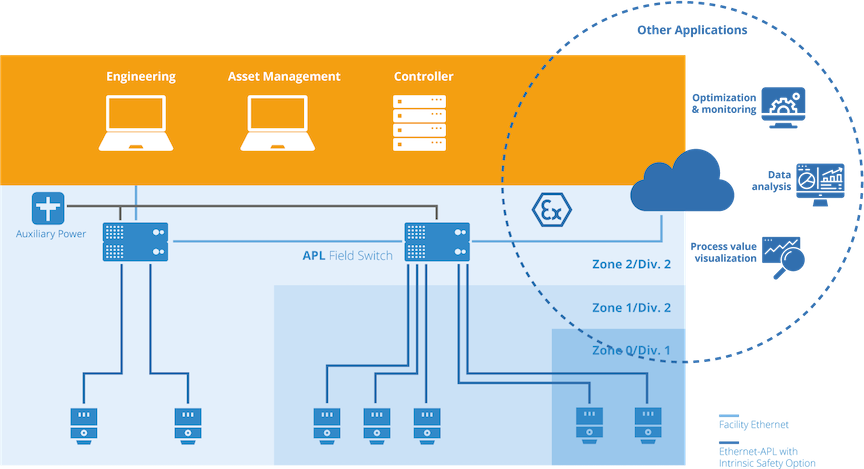

From Hazardous Areas to the Enterprise with Ethernet

Familiar Installation and Infrastructure

Ethernet-APL is the ruggedized, two-wire, loop-powered Ethernet physical layer that uses 10BASE-T1L plus extensions for installation within the demanding operating conditions and hazardous areas of process plants. It enables a direct connection of field devices to Ethernet-based systems in a way that process industries can benefit from a convergence of their OT and IT systems. Utilizing a switched architecture, eliminates any unwanted interference between devices connected to the same network.

Ethernet-APL adopts technologies and options already established in the field of process automation. This includes the proven trunk-and-spur topology shown in the figure above with the ability to power up to 50 field devices with up to 500 mW each. Widely used and established cable infrastructures are specified to support the migration in brown field installations to Ethernet-APL

Key Benefits

Only Two Wires

By using two conductor cabling, that may be already be installed in a facility, Ethernet-APL can offer an attractive technology upgrade value proposition.

Conformance

Devices and components are required to undergo conformance testing to assure that all critical Ethernet-APL features are implemented properly.

Familiar Installation

Using proven FISCO practices helps assure proper installation — first time, and every time.

Milestones